|

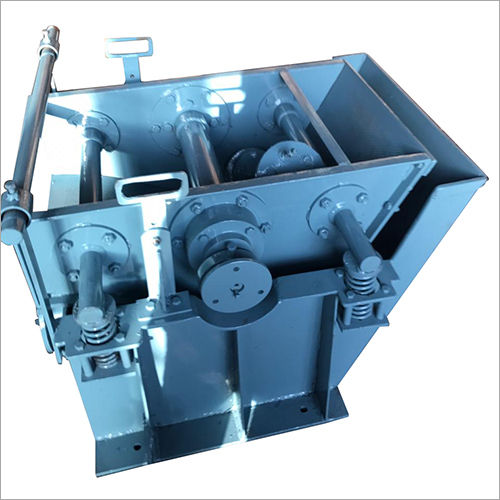

Beater Washing Drum

Beater Washing Drum Specification

- Grade

- Industrial Grade

- Type

- Beater Washing Drum

- Material

- Stainless Steel

- Capacity

- 30-100 kg

- Computerized

- No

- Control System

- Manual

- Voltage

- 220-240 V

- Power

- 1-2 HP

- Weight (kg)

- 80-250 kg

- Dimension (L*W*H)

- Varies with Capacity

- Color

- Silver

Beater Washing Drum Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Day

- Delivery Time

- 2 Months

About Beater Washing Drum

Owing to its salient features such as carbide tungsten steel structure, smooth operational handling, easy to use and minimum maintenance. Paper Beater Washing Drum is processed in a well established administrate premises to deliver anti-corrosive and defect free device to clients. Proposed unit is carved out with beating rag waste into the paper pulp material. We render Paper Beater Washing Drum in different technical specifications and dimensional accuracy to honored consumers. Moreover, this drum can easily withstand with heavy compression and tough climatic situations.

Stainless Steel Excellence and Long-Term Durability

Constructed from top-quality stainless steel, the Beater Washing Drum delivers resilience against harsh conditions in textile and laundry facilities. The anti-corrosive surface treatment protects your investment from rust and chemical damage, while the mirror-polished drum finish ensures easier maintenance and a lasting shine.

Industrial-Grade Performance for Heavy Loads

With capacities from 30 to 100 kg and a power range of 12 HP, this washing drum is well-suited for medium to large-scale operations. Low-noise operation combined with heavy-duty paddle beaters guarantees efficient agitation, thorough cleaning, and gentle handling of fabrics, meeting demanding industrial standards.

Safe and User-Friendly Operation

Equipped with manual controls, a hinged door with a secure locking system, and overload protection, the drum emphasizes safety and straightforward usage. The front-loading design and free-standing mounting offer convenience and flexibility, while the adjustable drum rotation speed (1540 RPM) caters to various washing requirements.

FAQs of Beater Washing Drum:

Q: How does the beater washing drum achieve effective cleaning for textiles and laundry?

A: The drum utilizes heavy-duty paddle beaters that agitate fabrics thoroughly during washing, ensuring deep and uniform cleaning. Its cylindrical shape promotes even water distribution, while the front-loading design allows for efficient handling and processing of large loads.Q: What are the benefits of the anti-corrosive coating and mirror polish finish?

A: The anti-corrosive coating safeguards the washing drum against rust and chemical exposure, extending its operational lifespan. Meanwhile, the mirror polish finish makes the drum easier to clean, reducing the likelihood of residue buildup and maintaining hygiene standards.Q: When is it appropriate to use this washing drum in an industrial setting?

A: This beater washing drum is best utilized in scenarios involving high-volume textile or laundry processing, such as commercial laundries, textile manufacturing units, and institutional facilities. Its robust construction and large capacity are ideal for demanding, repeated cycles.Q: Where can this drum be installed within a facility?

A: Designed as a free-standing unit, the washing drum can be placed in any suitable area with adequate space and access to power (220-240 V) and water supply. Its dimensions vary by capacity, so installation location should accommodate the selected models footprint.Q: What is the recommended process for operating the washing drum safely?

A: Users should load textiles evenly, secure the hinged door using its locking mechanism, and select desired settings via the manual control system. The built-in overload protection prevents damage from excessive loads, ensuring smooth and safe operation throughout the cycle.Q: How does the overload protection feature enhance operational safety?

A: The overload protection system automatically detects if the load exceeds safe limits. In such cases, it halts operation or prevents the cycle from starting, reducing the risk of mechanical failure and ensuring the safety of both users and equipment.Q: What sets this beater washing drum apart from conventional models?

A: This model stands out for its industrial-grade stainless steel build, low noise level, anti-corrosive surface, heavy-duty paddle design, overload protection, and capacity to handle large textile loads. These features collectively ensure high performance, longevity, and reliable results in professional settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pulp And Paper Machinery Category

Pulper Machine

Minimum Order Quantity : 1 Set

Cutting Size : Varies as per sieve selection

Weight (kg) : 90120 kg

Grade : Other, Food Grade

Control System : Other, Manual

Cutting Speed : 15001800 kg/hr

Hydra Pulper Machine

Minimum Order Quantity : 1 Set

Cutting Size : Customizable as per requirement

Weight (kg) : 2000 kg (approx.)

Grade : Other, Industrial Grade

Control System : Other, Automatic/Manual

Cutting Speed : 1500 rpm

Beater Machine

Minimum Order Quantity : 1 Set

Cutting Size : 24 mm (adjustable)

Weight (kg) : Approx 350 kg

Grade : Other, Industrial

Control System : Other, Manual

Cutting Speed : 450500 kg/hr

|

GURPAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry