|

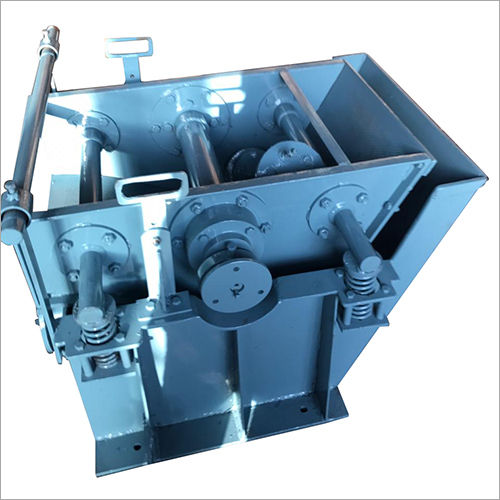

Pulper Machine

Pulper Machine Specification

- Grade

- Food Grade

- Type

- Pulper Machine

- Material

- Stainless Steel

- Capacity

- Up to 2 tons/hr

- Computerized

- No

- Control System

- Manual

- Cutting Speed

- 1500-1800 kg/hr

- Cutting Size

- Varies as per sieve selection

- Cutting Thickness

- Adjustable

- Voltage

- 220-240 V

- Power

- 2-5 HP

- Weight (kg)

- 90-120 kg

- Dimension (L*W*H)

- 900 x 450 x 700 mm

- Color

- Silver

Pulper Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Day

- Delivery Time

- 2 Months

About Pulper Machine

Due to optimal performance and less maintenance, we are engaged in providing a comprehensive assortment of Horizontal Type Hydrapulper Machine. It is fabricated with strong steel and metal structure to deliver the accurate fiber length and intensity nature. This machine is utilized in the paper mill for separating pulp board, breaking waste paper material under high consistency. Horizontal Type Hydrapulper Machine helps to enhanced the high density under the ambient temperature condition. It produces strong friction and prevents bacteria in the damaged paper.

Versatile and Efficient Pulping

This Pulper Machine is designed to handle a variety of produce, from soft fruits like mango and papaya to firmer options such as apples and guavas. The adjustable sieve allows you to select the desired pulp consistency, making it suitable for multiple applications in both small and large-scale operations. Its continuous operating mode enables uninterrupted, high-volume production.

User-Friendly Maintenance and Cleaning

Maintenance is straightforward thanks to the removable sieve and accessible design. Operators can quickly clean and reassemble the machine, reducing downtime and ensuring consistent hygiene standards. The sturdy, stainless-steel build resists corrosion, while overload protection enhances operator safety. Minimal maintenance is required, making it a reliable addition to any processing facility.

FAQs of Pulper Machine:

Q: How does the Pulper Machine ensure easy cleaning and maintenance?

A: The machine features a removable sieve that simplifies the cleaning process. Its accessible design enables operators to dismantle key parts for thorough washing, while the stainless-steel construction resists corrosion, making maintenance effortless and ensuring longevity.Q: What types of fruits and vegetables can be processed with this pulper?

A: This machine is suitable for a wide assortment of fruits and vegetables, such as tomatoes, mangoes, guavas, papayas, and apples. The adjustable sieve settings allow you to process items into either fine or coarse pulp, depending on your needs.Q: When should I adjust the sieve for different cutting thickness?

A: You should select the appropriate sieve and adjust the cutting thickness according to the pulp consistency required by your end product. For example, finer sieves are ideal for juices and pures, while coarser sieves work best for products needing chunkier pulp.Q: Where is this Pulper Machine best installed?

A: Being floor-mounted and moderately compact (900 x 450 x 700 mm), the machine is best suited for use in commercial kitchens, food processing plants, or export-oriented packing units. It requires a stable surface and sufficient space for operation and cleaning.Q: What benefits does this machine offer for bulk processing applications?

A: Equipped with a large feeding hopper and capable of processing up to 2 tons per hour, the Pulper Machine is ideal for bulk operations. Its high cutting speed, continuous operating mode, and low power consumption maximize productivity while minimizing operational costs.Q: How does the machine contribute to energy efficiency and safety?

A: The pulper is designed for low power consumption (2-5 HP) without compromising productivity. It incorporates overload protection and operates with low noise, creating a safe and comfortable working environment.Q: What is the process for operating the Pulper Machine?

A: Feed the washed fruits or vegetables into the large input hopper. Select and fit the desired sieve based on required pulp consistency. The machine separates pulp from waste efficiently at 960 RPM. Afterwards, remove and clean the sieve for easy maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pulp And Paper Machinery Category

Beater Machine

Minimum Order Quantity : 1 Set

Material : Mild Steel

Dimension (L*W*H) : 1650 mm x 900 mm x 1250 mm

Control System : Other, Manual

Type : Other, Beater Machine

Voltage : 220240 V

Hydra Pulper Machine

Minimum Order Quantity : 1 Set

Material : Mild Steel (MS)

Dimension (L*W*H) : 3500 x 2200 x 2400 mm

Control System : Other, Automatic/Manual

Type : Other, Hydra Pulper Machine

Voltage : 415 V

Beater Washing Drum

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Dimension (L*W*H) : Varies with Capacity

Control System : Other, Manual

Type : Other, Beater Washing Drum

Voltage : 220240 V

|

GURPAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry