|

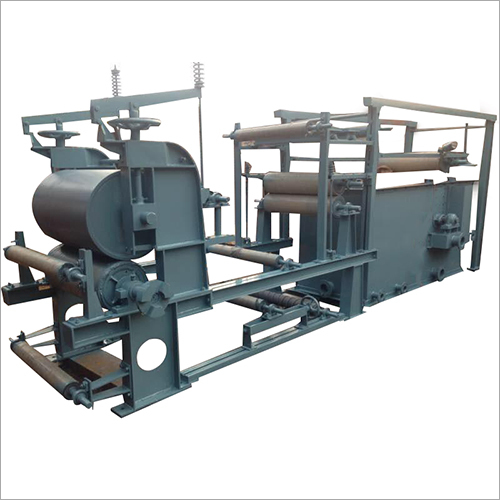

Cylinder Mould Paper Machine

Cylinder Mould Paper Machine Specification

- Grade

- Industrial

- Type

- Cylinder Mould Paper Machine

- Material

- Mild Steel, Stainless Steel

- Capacity

- 10 - 300 TPD

- Computerized

- Yes

- Control System

- PLC Automatic Control System

- Cutting Speed

- Up to 200 m/min

- Cutting Size

- 600-3200 mm

- Cutting Thickness

- 0.1-10 mm (depends on pulp & configuration)

- Voltage

- 380V/415V/440V (customized)

- Power

- 45-150 kW (Model dependent)

- Weight (kg)

- 20000 - 120000 kg (Based on model)

- Dimension (L*W*H)

- Customizable, Typical: 30m x 5m x 4m

- Color

- Industrial Green/Grey/Custom

Cylinder Mould Paper Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Month

- Delivery Time

- 2 Months

About Cylinder Mould Paper Machine

Single Cylinder Mould Toilet Paper Making Machine helps to decrease the level of garbage like waste paper book, waste paper etc. It is used to make toilet paper by recycling various types of waste paper materials. Owing to its great mechanism and capable to function uninterrupted performance without involving any quick maintenance service. This machine delivers smooth paper without facing any tearing or cracking issue. Single Cylinder Mould Toilet Paper Making Machine is equipped with tough tools to tackle the heavy weight and hard temperature easily.

Advanced Automation and Control

Equipped with a PLC automatic control system and computerized interface, this cylinder mould paper machine ensures seamless operations and precise process management. Variable frequency drive technology enables consistent speed control, optimizing both operational efficiency and energy consumption. Users benefit from intuitive system diagnostics and programmable functionality, speeding up changeovers and reducing downtime.

Flexible Production and Material Versatility

The machine supports a wide GSM range (40300 gsm) and can process various raw materials such as waste paper, wood pulp, and bamboo pulp. Designed to produce kraft paper, test liner, corrugated board, and standard writing paper, it meets diverse market requirements. Modular sectionssingle or multi-wire, cylinder dryer, and multiple press rollersallow for tailored configurations to fit different production goals.

Robust Build and Long Service Life

Manufactured from premium mild steel and stainless steel, the machine is built to endure heavy industrial usage. With a service life extending up to 20 years and a capacity of 10300 TPD, it is ideal for large-scale paper manufacturers. Its customizable size and configuration make it suitable for various operational spaces, while professional installation and reliable after-sales support further enhance operational continuity.

FAQs of Cylinder Mould Paper Machine:

Q: How does the automatic cylinder mould paper machine process different types of raw materials?

A: The machine is designed to handle waste paper, wood pulp, or bamboo pulp as feedstock. The pulping system preprocesses these materials and feeds the pulp to the wire and press sections, where it is formed, pressed, and dried into kraft paper, writing paper, test liner, or corrugated board. Flexible configuration and PLC control ensure consistent output across all material types.Q: What are the benefits of using variable frequency drive (VFD) for speed regulation in this paper machine?

A: Variable frequency drive (VFD) allows precise control of machine speeds, which optimizes energy consumption, minimizes mechanical wear, and enables smooth adjustments during production. This leads to higher efficiency, lower operational costs, and improved product quality.Q: When is installation and commissioning of the machine carried out, and by whom?

A: Installation and commissioning are provided by the manufacturer immediately after delivery and site preparation. A team of skilled engineers handles the setup, calibration, and initial test runs to ensure smooth operation from the outset.Q: Where can the machine be customized to fit specific operational dimensions and needs?

A: The cylinder mould paper machine is highly adaptable and can be customized by the manufacturer regarding size, configuration, and electrical specifications, depending on your production requirements and space constraints.Q: What is the typical service life and after-sales support coverage for this equipment?

A: The machine is engineered for a service life of 1520 years, thanks to its durable mild steel and stainless steel construction. Comprehensive after-sales support, including technical assistance, spare parts, and maintenance services, is readily available for ongoing reliability.Q: How is water consumption managed during the paper-making process?

A: This machine uses water efficiently, consuming only 5-15 m per ton of finished paper. Advanced water management systems and efficient cylinder drying contribute to minimized water usage and environmental impact.Q: What are the main advantages of using this automatic paper machine in industrial settings?

A: Key advantages include high production capacity (10300 TPD), automation with PLC control for consistent quality, robust build for longevity, flexible material compatibility, low operational costs, and professional technical support throughout the machines lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hand Made Paper Machinery Category

Industrial Rag Chopper

Minimum Order Quantity : 1 Set

Control System : Other, Manual

Grade : Other, Industrial Grade

Color : Blue and Yellow

Voltage : 415 V

Weight (kg) : 650 kg

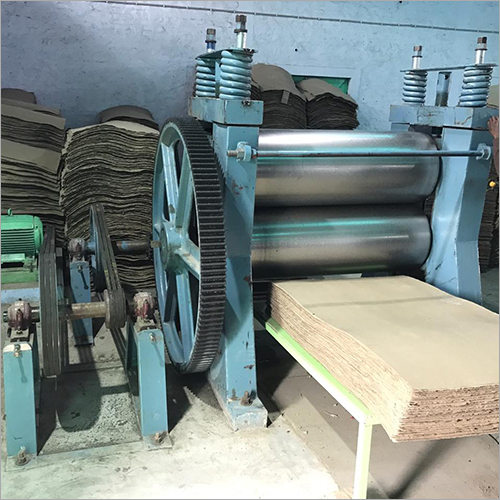

Calendaring Machine

Minimum Order Quantity : 1 Set

Control System : PLC Control

Grade : Other, Industrial Grade

Color : Blue & Grey

Voltage : 380V / 415V, 3 Phase

Weight (kg) : Approx. 3200 kg

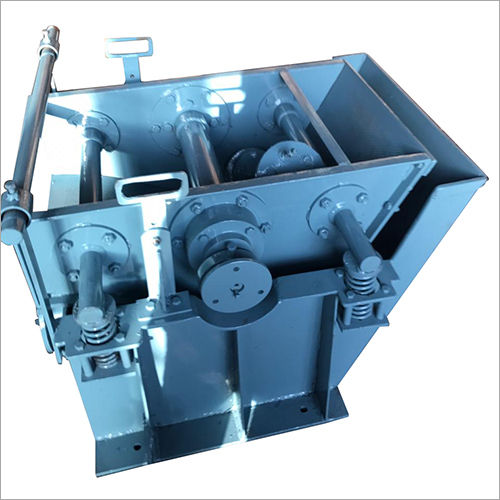

Hydraulic Press

Minimum Order Quantity : 1 Set

Control System : Other, Manual/PLCbased

Grade : Other, Industrial Grade

Color : Blue & Yellow

Voltage : 220V/380V, 50/60Hz

Weight (kg) : Approx. 1800 kg

Waste Paper Recycling Mini Beater

Minimum Order Quantity : 1 Set

Control System : Other, Manual

Grade : Other, Industrial

Color : Green & Silver

Voltage : 220240 V (Single Phase)

Weight (kg) : Approximately 200 kg

|

GURPAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry