|

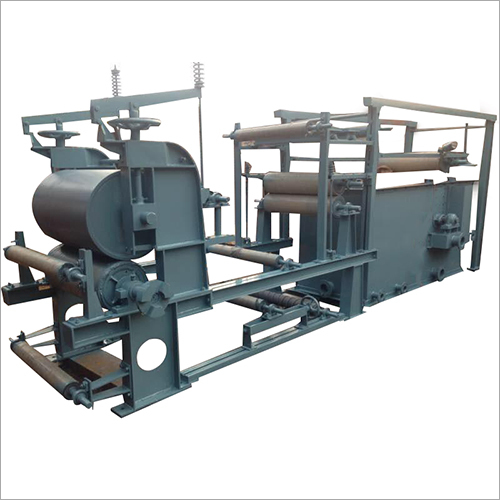

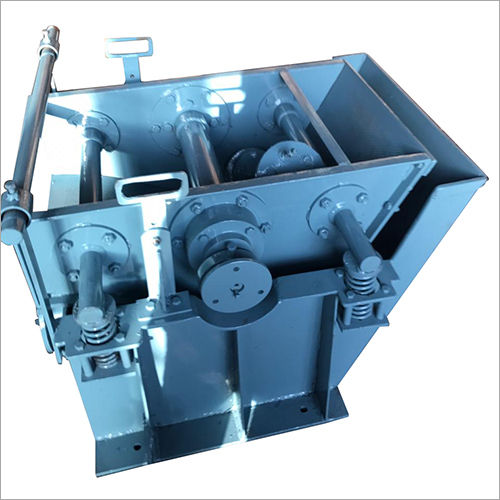

Hydraulic Press

Hydraulic Press Specification

- Grade

- Industrial Grade

- Type

- Hydraulic Press

- Material

- Mild Steel

- Capacity

- 50 Ton

- Computerized

- No

- Control System

- Manual/PLC-based

- Cutting Speed

- Variable, up to 150 mm/sec

- Cutting Size

- Customizable, up to 600 x 600 mm

- Cutting Thickness

- Up to 20 mm (depending on material)

- Voltage

- 220V/380V, 50/60Hz

- Power

- 5 kW

- Weight (kg)

- Approx. 1800 kg

- Dimension (L*W*H)

- 2200 x 1200 x 1800 mm

- Color

- Blue & Yellow

Hydraulic Press Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets, , Per Month

- Delivery Time

- 2 Months

About Hydraulic Press

We are popular amongst our clients by presenting a huge series of Manual Screw Press Machine. It is used for hot fording of stamping, cold coining, non ferrous metal products, carbon steel material, brass, aluminum and other steel materials. This machine is manufactured with the cast iron and modern tools. Manual Screw Press Machine can be operated easily by pressing a provided lever from left side column on the front side of the pressing system. It ensures high energy efficiency and noise free performance.

Reliable Steel Frame Structure

Built with a robust, welded mild steel frame, this hydraulic press boasts outstanding durability, stability, and resistance to deflection during intensive tasks. Its design ensures consistent force throughout each operation, making it ideal for challenging jobs in industrial environments. The powder-coated finish enhances corrosion resistance, extending the lifespan and preserving the professional appearance of the equipment.

Flexible and Precise Operation

Equipped with a double-acting pump and hydraulic lever, this press delivers precise movement and efficient force for each stroke. Operators benefit from variable cutting speeds up to 150 mm/sec, a 250 mm stroke length, and an ergonomic 700 mm working table height. Both manual and PLC-based controls are available for flexibility in diverse industrial processes including cutting, bending, and forming.

Safety and Customization in Focus

Safety is a chief consideration, with overload protection integrated into the system to prevent accidents and equipment damage. The press also features a standard fitted pressure gauge for close monitoring. Customization options for cutting sizeup to 600 x 600 mmand material thickness (up to 20 mm) allow adaptation to specific project requirements, maximizing productivity.

FAQs of Hydraulic Press:

Q: How does the hydraulic press ensure safety during operation?

A: Safety is prioritized through features like overload protection to guard against excessive pressure and a standard fitted pressure gauge for monitoring. These measures help prevent damage and ensure safe usage during high-intensity industrial tasks.Q: What applications can this hydraulic press be used for?

A: This hydraulic press is well-suited for moulding, punching, bending, forming, and cutting applications, making it ideal for various industrial manufacturing processes that require strength, precision, and adaptability.Q: When should I choose the manual versus PLC-based control system?

A: Choose the manual lever operation for straightforward, hands-on tasks or when automation is not necessary. The PLC-based control system is ideal for more complex, repetitive, or automated processes requiring programmable settings and enhanced precision.Q: Where is this hydraulic press manufactured and supplied from?

A: The press is manufactured, exported, and supplied from India, catering to both domestic and international industrial markets seeking reliable hydraulic machinery.Q: What process is involved in setting up and operating the hydraulic press?

A: Setting up involves placing the press on a stable surface, connecting it to a compatible voltage power source (220V/380V, 50/60Hz), and ensuring the oil tank is filled to its 60-liter capacity. Operators can select manual or PLC control to run the desired processes including cutting, bending, or moulding.Q: How is the cutting size and thickness customized?

A: The cutting size can be customized up to 600 x 600 mm, and the thickness is adjustable depending on the material, with a maximum of 20 mm. This flexibility allows users to tailor the machines output to suit specific production requirements.Q: What benefits does the robust steel welded structure provide?

A: The solid welded mild steel frame offers excellent durability, stability, and the capacity to withstand 50-ton loads without warping or stress, ensuring reliable performance over a long service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hand Made Paper Machinery Category

Calendaring Machine

Minimum Order Quantity : 1 Set

Weight (kg) : Approx. 3200 kg

Voltage : 380V / 415V, 3 Phase

Computerized : Yes

Power : 10 kW

Dimension (L*W*H) : 4200 x 1800 x 1950 mm

Cylinder Mould Paper Machine

Minimum Order Quantity : 1 Set

Weight (kg) : 20000 120000 kg (Based on model)

Voltage : 380V/415V/440V (customized)

Computerized : Yes

Power : 45150 kW (Model dependent)

Dimension (L*W*H) : Customizable, Typical: 30m x 5m x 4m

Industrial Rag Chopper

Minimum Order Quantity : 1 Set

Weight (kg) : 650 kg

Voltage : 415 V

Computerized : No

Power : 5 HP

Dimension (L*W*H) : 1500 mm x 900 mm x 1250 mm

Waste Paper Recycling Mini Beater

Minimum Order Quantity : 1 Set

Weight (kg) : Approximately 200 kg

Voltage : 220240 V (Single Phase)

Computerized : No

Power : 2 HP Motor

Dimension (L*W*H) : About 1000 x 800 x 1200 mm

|

GURPAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry