|

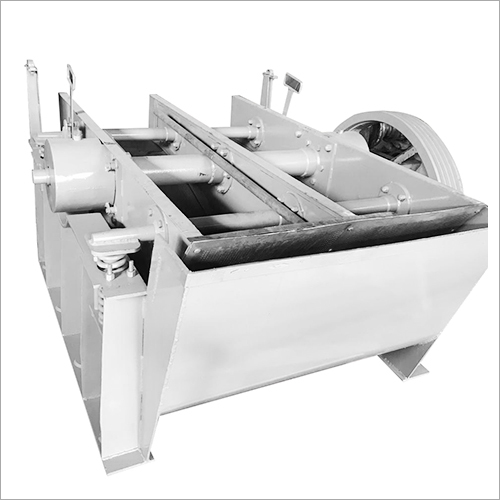

Pulp Vibrating Screen

Pulp Vibrating Screen Specification

- Grade

- Industrial

- Type

- Vibrating Screen

- Material

- Stainless Steel

- Capacity

- 8 - 40 TPD

- Computerized

- No

- Control System

- Manual

- Voltage

- 380 V

- Power

- 2.2 kW

- Weight (kg)

- Approx. 900 kg

- Dimension (L*W*H)

- 1800 x 900 x 1200 mm

- Color

- Silver

Pulp Vibrating Screen Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Month

- Delivery Time

- 2 Months

About Pulp Vibrating Screen

Efficient Fiber Screening

The advanced design of the vibrating screen optimizes pulp screening, enabling effective separation and removal of contaminants. Its customizable mesh and adjustable vibration frequency ensure precise results and minimal fiber loss, which are crucial for high-quality paper production.

Durability and Low Maintenance

Constructed from high-grade stainless steel, the vibrating screen offers a robust build and resistance to corrosion or wear. Easy access features simplify routine maintenance, ensuring prolonged uptime and reducing operational interruptions in busy pulp and paper facilities.

Adaptable for Industrial Needs

The machine is versatile, supporting both single and double-layer screen configurations. Horizontal installation and automatic discharge make integration seamless within different processing lines. Manual control allows operators to optimize operation according to specific pulp consistency and output demands.

FAQs of Pulp Vibrating Screen:

Q: How does the pulp vibrating screen operate within the pulp and paper industry?

A: The vibrating screen uses a three-phase induction motor and an eccentric shaft to produce controlled vibrations. As pulp flows through the stainless-steel mesh, fibers are efficiently separated from contaminants, supporting cleaner pulp and improving the quality of the end product.Q: What are the benefits of customizable screen mesh sizes between 0.2 to 3 mm?

A: Customizable mesh sizes allow users to select the most suitable screening parameters for different pulp types. This enables precise separation, supports varying fiber dimensions, and adapts easily to shifting production requirements or grades.Q: When should the screen layer configuration be chosensingle or double layer?

A: The choice depends on the level of impurities in the pulp and the screening efficiency desired. Single layers are typically used for lighter, cleaner pulp streams, while double layers are preferable for applications requiring enhanced separation and higher throughput.Q: Where is the best place to install the vibrating screen?

A: The unit is designed for horizontal installation within pulp processing lines, ideally positioned before the stock preparation stage or within the screening section. Its compact footprint fits easily into existing setups, maximizing processing efficiency.Q: What process steps are involved in maintaining the vibrating screen?

A: Routine maintenance involves periodic inspection of mesh, lubrication of moving parts, checking the eccentric shaft, and verifying motor function. The design ensures these tasks can be completed quickly, minimizing downtime and keeping operation smooth.Q: How does the low noise level of the vibrating screen benefit the workspace?

A: Low operational noise enhances the factory environment, reducing worker fatigue and ensuring compliance with industrial noise regulations. It also facilitates safer communication among staff near the machine.Q: What is the usage capacity range of this vibrating screen, and can it be customized for larger operations?

A: Standard capacity ranges from 8 to 40 TPD, accommodating both small and large-scale pulp processing. For expansive industrial needs, mesh sizes, motor specifications, and screen configurations can be tailored during manufacturing by the supplier.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hand Made Paper Machinery Category

Industrial Rag Chopper

Minimum Order Quantity : 1 Set

Voltage : 415 V

Grade : Other, Industrial Grade

Control System : Other, Manual

Color : Blue and Yellow

Weight (kg) : 650 kg

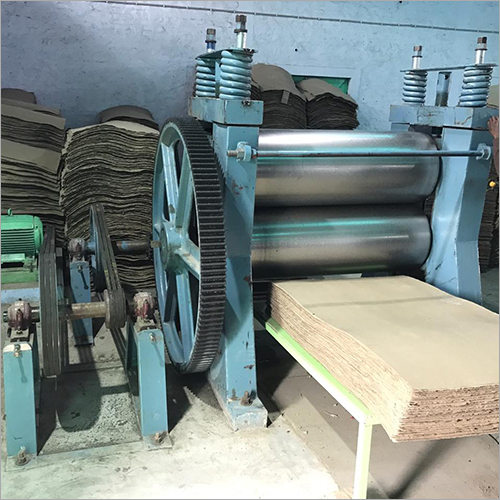

Calendaring Machine

Minimum Order Quantity : 1 Set

Voltage : 380V / 415V, 3 Phase

Grade : Other, Industrial Grade

Control System : PLC Control

Color : Blue & Grey

Weight (kg) : Approx. 3200 kg

Waste Paper Recycling Mini Beater

Minimum Order Quantity : 1 Set

Voltage : 220240 V (Single Phase)

Grade : Other, Industrial

Control System : Other, Manual

Color : Green & Silver

Weight (kg) : Approximately 200 kg

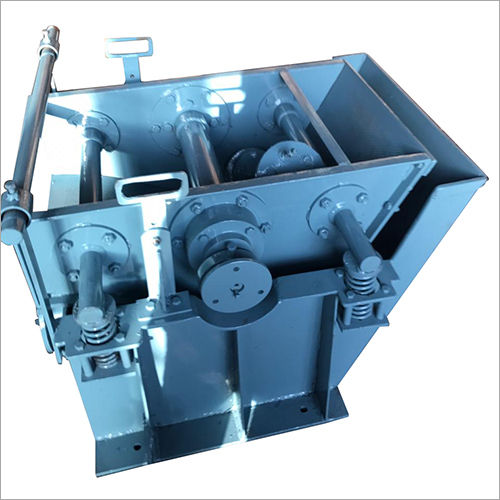

Single Deck Vibrating Screen

Minimum Order Quantity : 1 Set

Voltage : 220440 V

Grade : Other, Industrial

Control System : Other, Manual

Color : Yellow & Black

Weight (kg) : Approx. 5001500 kg

|

GURPAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry