|

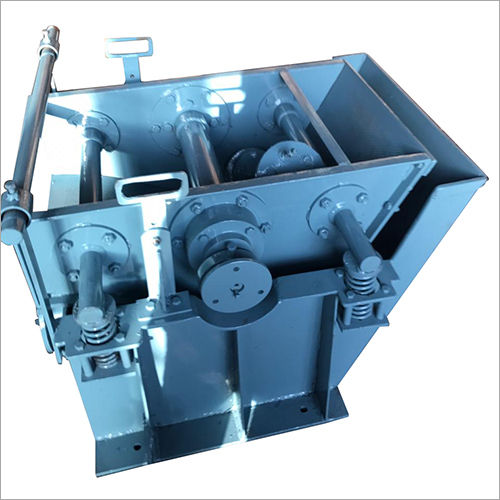

Calender Machine

Calender Machine Specification

- Type

- Rolling Calender Machine

- Material

- Mild Steel (MS)/Cast Iron constructed

- Computerized

- No

- Cutting Speed

- Variable, up to 30 m/min m/m

- Cutting Size

- Customizable as per requirement

- Cutting Thickness

- Up to 15 mm Millimeter (mm)

- Voltage

- 380V/415V, 3 Phase, 50-60 Hz Volt (v)

- Power

- 7.5 kW Watt (w)

- Weight (kg)

- Approx. 3500 kg Kilograms (kg)

- Dimension (L*W*H)

- 3400 x 1400 x 1800 mm Millimeter (mm)

- Color

- Sky Blue/Grey

Calender Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Month

- Delivery Time

- 2 Months

About Calender Machine

Mini Binding Plastic Paper Calendar Crimping Machine is build to punch the holes for plastic binding materials. Used for combining the two nonferrous metal piece through bending processing system. It is supervised under the observation of experienced engineers using hi-tech components which can easily repair in future. Mini Binding Plastic Paper Calendar Crimping Machine doesnt provide any noise and give trouble free performance. Provided machine is easy to install due to its great strength and weather proof nature.

FAQs of Calender Machine:

Q: How does the roller configuration affect sheet processing in the calender machine?

A: The number of rollers (ranging from 2 to 5) impacts the thickness, finish, and overall quality of the processed material. More rollers enable finer calibration and uniformity, accommodating different sheet types and desired textures like mirror or matt finishes.Q: What materials can be processed using this calender machine?

A: This calender machine is suitable for PVC, rubber, textile, and synthetic leather sheets. Its robust construction and customizable settings allow efficient handling of various material properties and thickness requirements, making it versatile for multiple industries.Q: When should I choose oil, electric, or gas heating for the rollers?

A: The choice of heating system depends on specific production needs and energy availability. Oil heating ensures even temperature distribution, electric offers quick response, and gas can be cost-effective for continuous operations. All options can heat rollers up to 250C, ensuring optimal processing conditions.Q: Where can the calender machine be installed, and is support provided?

A: This machine is designed for industrial settings such as manufacturing plants or processing units. On-site installation support and after-sales service are available, ensuring seamless integration and continued operational reliability.Q: What is the typical process for setting up and operating the calender machine?

A: The machine is installed and leveled on-site, connected to a 380V/415V, 3-phase power supply. Operators manually configure roller pressure, temperature, and cutting parameters using interlocked controls, then feed the material to begin the calendering process.Q: How does the safety system benefit operators during machine use?

A: The machine includes emergency stop features, overload protection, and guard covers to prevent accidents and equipment damage. Manual controls with safety interlocks further ensure that only authorized personnel can operate or adjust the settings, enhancing workplace safety.Q: What are the main advantages of using this industrial calender machine?

A: Key benefits include high processing efficiency, customizable output for different materials and finishes, low operational noise (<75 dB), robust safety systems, and flexible support through on-site installation and after-sales service. This makes it ideal for continuous production environments demanding reliable output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Straw Board Mill And Card Board Machinery Category

Wood Chipper Machine

Minimum Order Quantity : 1 Set

Voltage : 220440 V

Type : Other, Wood Chipper Machine

Cutting Speed : 1440 RPM

Cutting Thickness : Up to 10 inches

Color : Blue & Yellow

Cylinder Mould Machine

Minimum Order Quantity : 1 Set

Voltage : 220V / 380V / 415V

Type : Other, Cylinder Mould Machine

Cutting Speed : 30 200 m/min

Cutting Thickness : 0.1 1.2 mm

Color : Standard Industrial Grey / Custom

|

GURPAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry