|

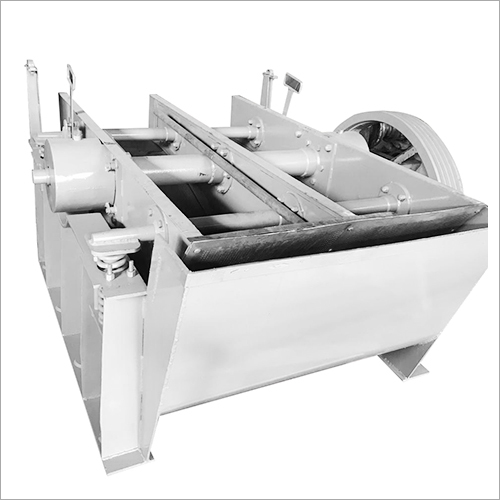

Calendaring Machine

Calendaring Machine Specification

- Grade

- Industrial Grade

- Type

- Automatic

- Material

- Mild Steel

- Capacity

- 500-1200 kg/hr

- Computerized

- Yes

- Control System

- PLC Control

- Cutting Speed

- 15-30 m/min

- Cutting Size

- Up to 2100 mm width

- Cutting Thickness

- 0.1 mm - 6 mm

- Voltage

- 380V / 415V, 3 Phase

- Power

- 10 kW

- Weight (kg)

- Approx. 3200 kg

- Dimension (L*W*H)

- 4200 x 1800 x 1950 mm

- Color

- Blue & Grey

Calendaring Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets, , Per Month

- Delivery Time

- 2 Months

About Calendaring Machine

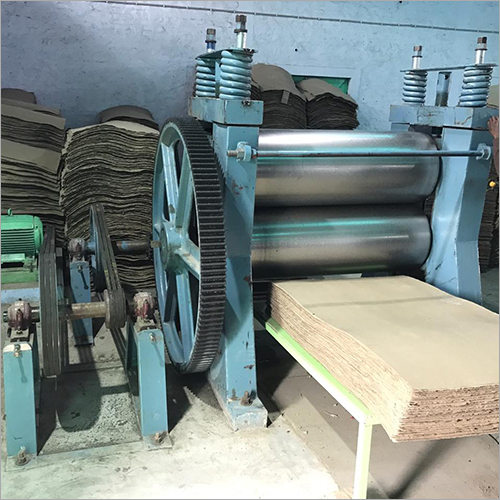

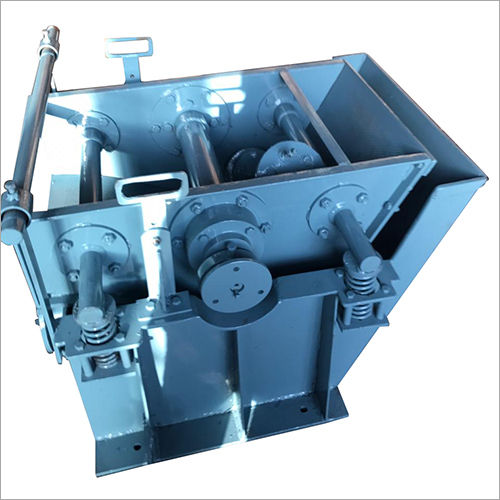

Paper Calendar Crimping Machine is formulated with heavy duty steel structure which is attached with different cylinders and double layer of formation. It is extensively demanded in the paper and other commercial sectors for its ultimate horsing power efficiency and self adjustments features. This machine is easy to operate with the aid of control panel system. Paper Calendar Crimping Machine consist quick line changeover which helps to compress the sheet and flexible to solve all the assorted types of technical problems.

Robust Performance and Configurability

This calendaring machine offers configurable roller options, supporting 3, 4, or 5 rollers depending on production requirements. Its industrial-grade mild steel build ensures durability, while the adjustable working pressure and variable cutting speed enhance processing versatility for different materials.

Safety and Automation at the Core

Integrated safety elements such as emergency stop buttons and full guard covers safeguard operators throughout production. The machine is fully automatic and computerized with PLC control, and the centralized automatic lubrication ensures smooth, uninterrupted operation.

Versatile Applications and Installation Support

Designed for processing rubber, PVC, PU, and textiles, this equipment suits manufacturers looking for precision and efficiency. Comprehensive installation service is available, assisting customers with quick setup and commissioning for seamless operations.

FAQs of Calendaring Machine:

Q: How does the calendaring machine ensure precise thickness and consistent surface quality for processed materials?

A: The machines PLC control system allows accurate setting of roller pressure and cutting thickness (from 0.1 mm to 6 mm), while mirror/chrome-finished rollers guarantee consistent, high-quality surface finish for rubber, PVC, PU, and textile applications.Q: What are the configurable options for rollers in this calendaring machine, and which materials do they suit best?

A: You can configure the machine with 3, 4, or 5 rollers. This flexibility accommodates various processing demands and helps optimize performance for different materials such as rubber sheets, plastic films, polyurethane foams, and textile fabrics.Q: When should you choose oil heating or electric heating for the calendaring machine?

A: Oil heating is recommended for applications requiring uniform temperature stability, especially in rubber or PVC processing. Electric heating offers quick temperature adjustments and is valuable for fast material turnover or frequent process changes.Q: Where can this calendaring machine be installed and what installation support is provided?

A: The machine is suitable for deployment in industrial manufacturing facilities in India or for export. Installation services are available to ensure correct setup, operator training, and smooth integration into existing production lines.Q: What is the typical process workflow for operating this calendaring machine?

A: Operators load the raw materials, configure the required roller number and pressure, select heating method, and set PLC-controlled parameters for desired thickness and width. Automatic lubrication maintains roller integrity during the process, while safety features protect personnel.Q: How does the centralized automatic lubrication system benefit machine usage and maintenance?

A: The centralized lubrication system continuously delivers oil to key mechanical parts, reducing wear, extending service life, and minimizing manual intervention. This helps maintain optimal roller performance and decreases downtime due to maintenance.Q: What advantages does this calendaring machine offer manufacturers in terms of efficiency and product quality?

A: With automated cutting speeds of 15-30 m/min, computer-controlled operation, and precise adjustment capabilities, manufacturers benefit from higher throughput, consistent material properties, and improved workplace safety, resulting in superior product quality and production reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hand Made Paper Machinery Category

Industrial Rag Chopper

Minimum Order Quantity : 1 Set

Weight (kg) : 650 kg

Voltage : 415 V

Type : Other, Industrial Rag Chopper

Grade : Other, Industrial Grade

Control System : Other, Manual

Hydraulic Press

Minimum Order Quantity : 1 Set

Weight (kg) : Approx. 1800 kg

Voltage : 220V/380V, 50/60Hz

Type : Other, Hydraulic Press

Grade : Other, Industrial Grade

Control System : Other, Manual/PLCbased

Single Deck Vibrating Screen

Minimum Order Quantity : 1 Set

Weight (kg) : Approx. 5001500 kg

Voltage : 220440 V

Type : Other, Single Deck Vibrating Screen

Grade : Other, Industrial

Control System : Other, Manual

Pulp Vibrating Screen

Minimum Order Quantity : 1 Set

Weight (kg) : Approx. 900 kg

Voltage : 380 V

Type : Other, Vibrating Screen

Grade : Other, Industrial

Control System : Other, Manual

|

GURPAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry